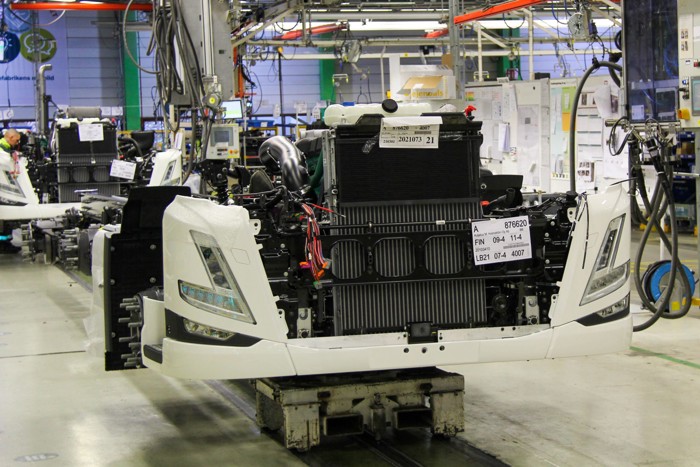

Challenge

Volvo Group Service Market Logistics (SML) faced challenges in managing and distributing spare parts across its global network. With a large inventory of parts stored in multiple warehouses and a complex supply chain, the organization struggled with outdated and fragmented data systems. The lack of centralized data visibility hindered their ability to track parts in real-time, predict inventory needs, and efficiently manage resources across various locations. The main objective was to centralize data into a unified platform to improve inventory management, streamline operations, and enhance the accuracy of supply chain forecasts.